In modern mold manufacturing, efficient and stable ejection is critical to product quality and production efficiency. The ejection sleeve, also known as ejector sleeve or sleeve ejector, is a key component within the mold ejection system, designed to ensure smooth, uniform part release without deformation or surface damage. As part of advanced injection mold components, ejector sleeves are widely used in injection molding, die casting, and stamping dies where precision and durability are essential.

What Is an Ejection Sleeve?

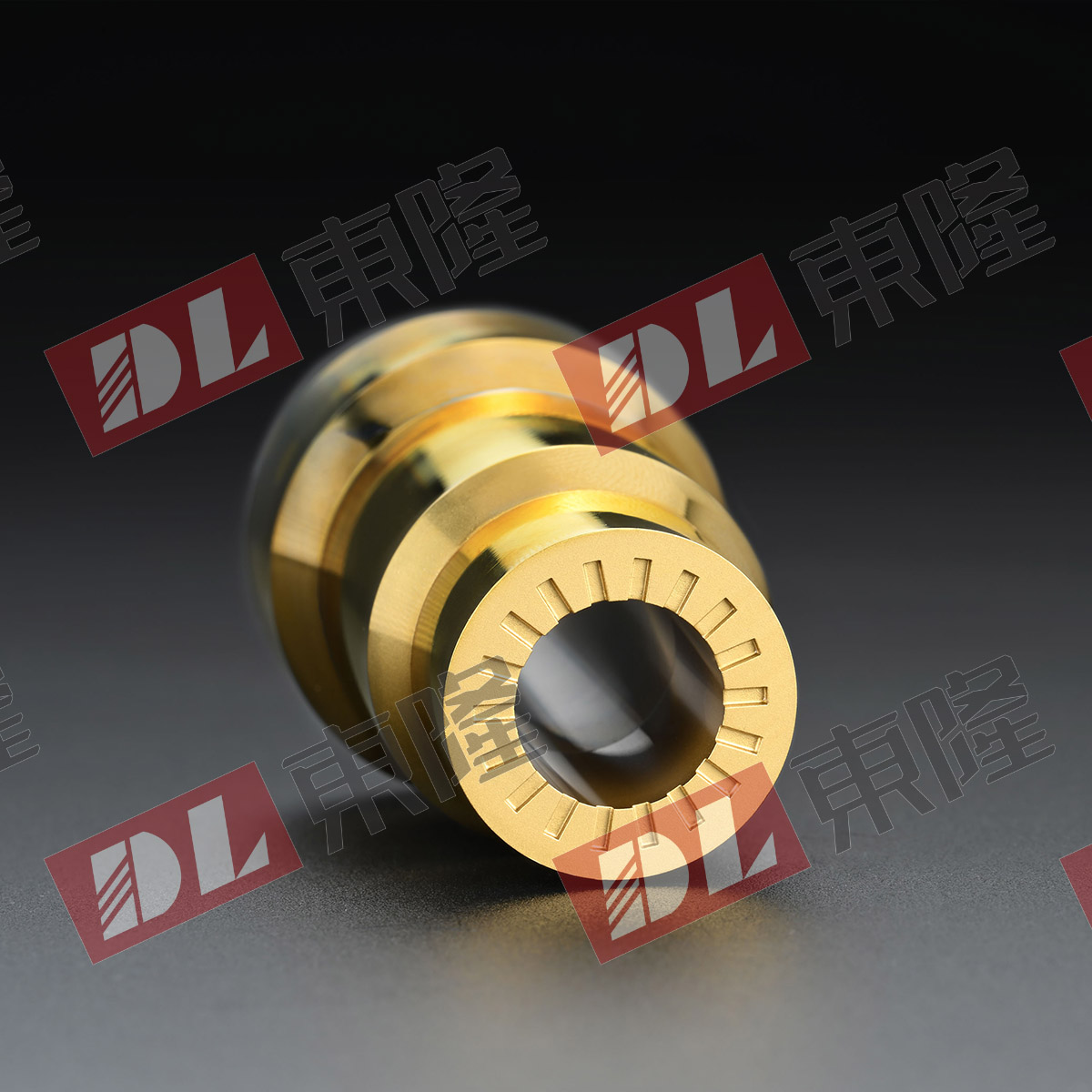

An ejection sleeve is a hollow ejecting element that works together with a core pin or shaft to push molded or formed parts out of the mold cavity. Compared to solid ejector pins, a mold ejector sleeve provides better force distribution and is ideal for parts with internal holes, bosses, or delicate geometries.

Depending on the application, it may also be referred to as a die ejector sleeve, injection mold ejector sleeve, or stamping die ejector sleeve, each optimized for different forming processes and load conditions.

Key Advantages of Sleeve Ejector Design

Uniform Ejection Force

The hollow structure of a sleeve ejector ensures even contact around the core, minimizing stress concentration and reducing the risk of part cracking or deformation.

High Wear Resistance

A tool steel ejector sleeve, typically made from H13, SKD61, or similar materials, offers excellent hardness and wear resistance, supporting long production cycles and high-volume manufacturing.

Precision Fit and Stability

As a precision ejector sleeve, tight tolerances on inner diameter, outer diameter, and concentricity ensure smooth movement and stable ejection performance even under high temperatures and pressures.

Wide Process Compatibility

Ejector sleeves are suitable for multiple molding and forming processes, including plastic injection molding, metal die casting, and stamping operations.

Applications Across Different Mold Types

Injection Molding

The injection mold ejector sleeve is commonly used in plastic molding for automotive, electronics, and medical components. It supports precise ejection of parts with deep cores or thin walls, improving yield and surface quality.

Die Casting

In high-temperature environments, a die casting ejector sleeve must withstand thermal fatigue and mechanical stress. Heat-treated tool steel and optimized surface finishes help maintain dimensional stability over long production runs.

Stamping Dies

A stamping die ejector sleeve assists in releasing formed metal parts smoothly, preventing scratches and ensuring consistent cycle times.

Precision Manufacturing and Customization

As a professional ejector sleeve manufacturer, precision machining is essential. Advanced CNC processes enable the production of high precision mold parts with tight tolerances and consistent quality.

Custom Ejector Sleeve Solutions

A custom ejector sleeve can be tailored to specific mold designs, including:

Customized inner and outer diameters

Special lengths and wall thicknesses

Surface treatments such as nitriding or polishing

OEM branding or part numbering

These OEM ejector sleeve solutions are especially valuable for mold makers seeking compatibility with proprietary mold designs or replacement parts.

Role in Injection Mold Components and Mold Ejection Systems

Within the full range of injection mold components, the ejector sleeve plays a vital role in the overall mold ejection system. Its performance directly affects mold life, cycle time, and finished part quality. When paired with other CNC machining mold components, a precision ejector sleeve contributes to smoother operation and reduced maintenance costs.

Choosing the Right Ejector Sleeve Manufacturer

When sourcing from a custom mold parts manufacturer, buyers should consider:

Material selection and heat treatment capability

Precision CNC machining experience

Quality control for concentricity and surface finish

Ability to supply OEM ejector sleeve solutions

Stable lead times and technical support

A reliable ejector sleeve manufacturer not only delivers consistent quality but also helps optimize mold performance through engineering support.

Whether referred to as an ejection sleeve, ejector sleeve, or sleeve ejector, this component is indispensable in modern mold design. From injection mold ejector sleeves to die ejector sleeves used in stamping and die casting, precision and durability are non-negotiable.

By choosing a high-quality tool steel ejector sleeve from an experienced custom mold parts manufacturer, mold makers and OEMs can achieve higher productivity, longer mold life, and superior product consistency—making the ejector sleeve a small component with a major impact.