In modern manufacturing, efficiency, accuracy, and durability are essential requirements for metal forming processes. The Six-Piece Combination Die is an advanced tooling solution designed to integrate multiple forming operations into a single Combination Die Set, significantly improving productivity and consistency. Widely used as a Metal Stamping Die, this system is engineered for high-volume production where precision and repeatability are critical.

What Is a Six-Piece Combination Die?

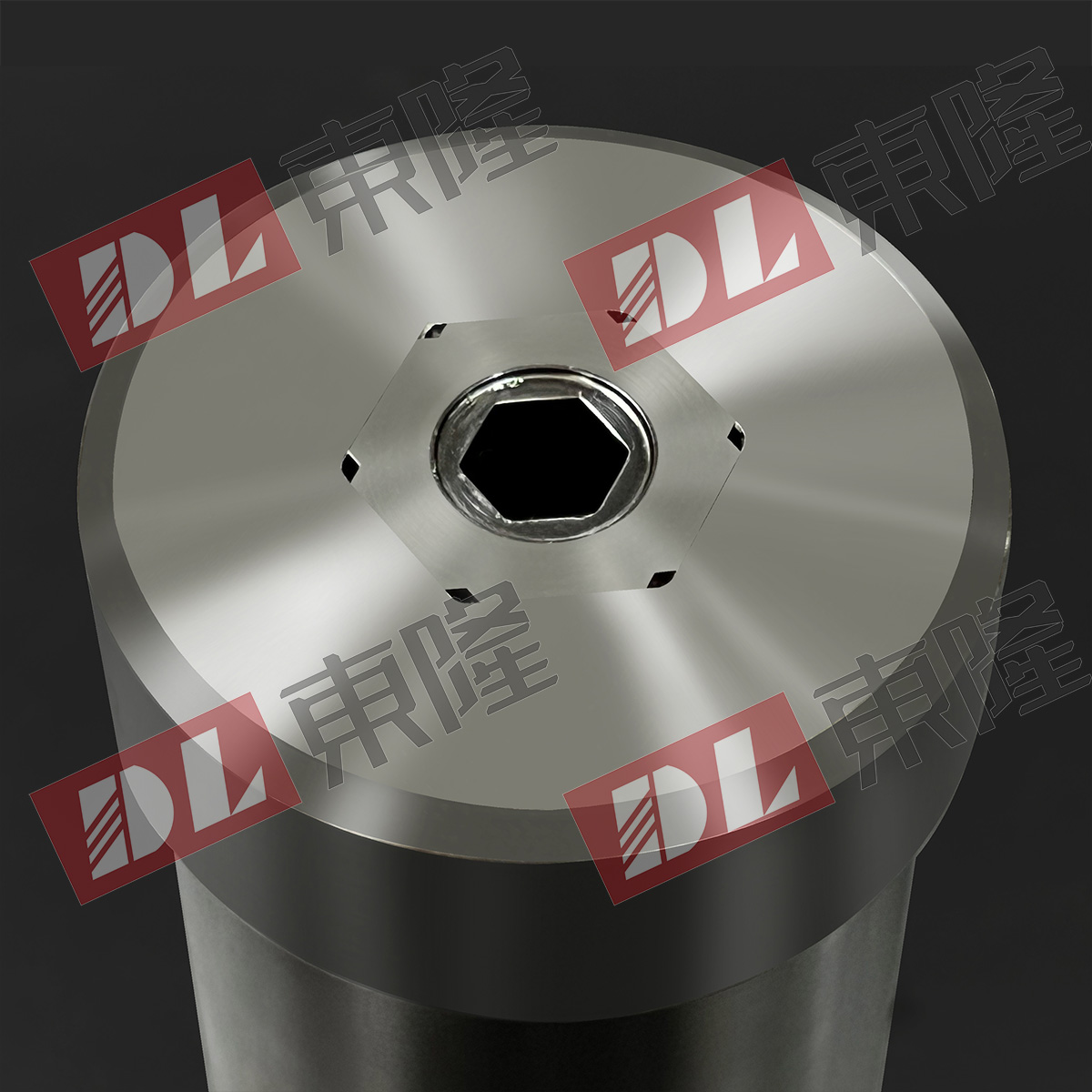

A Six-Piece Combination Die is a modular sheet metal die set composed of six precisely matched components working together within one tool. Unlike conventional single-operation dies, this precision combination die can perform punching, blanking, trimming, and forming in one press stroke.

As a die set for metal forming, it reduces secondary operations, shortens cycle time, and ensures stable dimensional accuracy across large production runs.

Key Features of Precision Combination Die Design

Integrated Multi-Operation Capability

The Combination Die Set integrates several metal forming steps into a single tooling system. This makes it an ideal metal stamping die for complex parts that require tight tolerances and consistent geometry.

CNC Machined Die Components

Each CNC machined die component is manufactured with high-precision machining, ensuring accurate alignment, smooth operation, and minimal wear. Advanced CNC and EDM processes guarantee repeatable quality and excellent surface finish.

High Precision and Durability

As a high precision die, the Six-Piece Combination Die is typically made from premium tool steel and undergoes heat treatment to achieve excellent hardness and wear resistance. This results in long service life, even under high-speed stamping conditions.

Modular and Customizable Structure

A custom combination die allows manufacturers to tailor the die structure according to specific product requirements. Replaceable inserts and modular design reduce maintenance costs and enable faster tool adjustments.

Applications of Six-Piece Combination Die

Sheet Metal Forming

The sheet metal die set is widely used in forming brackets, enclosures, connectors, and structural components where consistent dimensions are essential.

Industrial Manufacturing

As part of industrial die tools, combination dies are applied in automotive, electronics, hardware, and appliance manufacturing industries.

High-Volume Metal Stamping

The metal stamping die design is especially suitable for mass production, delivering stable output and reduced downtime.

Advantages Over Traditional Die Sets

Higher efficiency compared to single-operation dies

Reduced press strokes and tooling changes

Improved dimensional consistency

Lower overall production cost

Optimized workflow for industrial-scale manufacturing

These advantages make the precision combination die a preferred solution for manufacturers seeking reliability and scalability.

Custom Combination Die Manufacturing

A professional tooling supplier can provide custom combination die solutions based on part drawings, material specifications, and production volume requirements. Precision manufacturing of CNC machined die components ensures each die set for metal forming meets strict quality standards.

As a result, customers receive a fully optimized sheet metal die set designed for their exact application, enhancing productivity and minimizing long-term tooling costs.

The Six-Piece Combination Die represents an advanced and efficient approach to metal forming. As a high-performance Combination Die Set, it combines precision, durability, and flexibility into a single solution. Whether used as a metal stamping die, industrial die tool, or sheet metal die set, this high precision die delivers consistent results in demanding manufacturing environments.

For manufacturers seeking reliable, CNC-machined, and customizable tooling, the Six-Piece Combination Die is a proven solution for modern metal forming applications.