Moulds occupy a vital position in the manufacturing industry and are indispensable tools in production. As an innovative mould design, the Three-Piece Collapsible Mold (TPCM) shows significant advantages in the manufacturing industry with its unique structure and functions.

Definition and Structure of Three-Piece Collapsible Mold

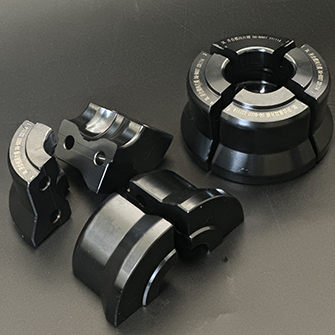

A three-piece foldable mould is a mould consisting of three main parts that can cooperate with each other to achieve the folding and unfolding functions during the operation of the mould. This design allows the mould to easily remove complex shaped workpieces from the mould during demoulding, avoiding the problem of difficult demoulding that may occur in conventional moulds.

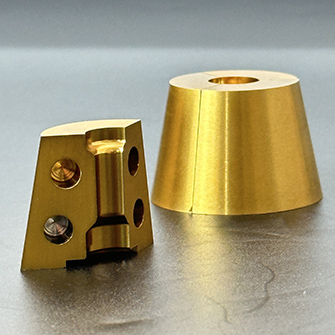

The Three-piece collapsible mould is mainly composed of the following three parts:

Core: The core is the main forming part of the mould, which determines the internal and external shapes of the workpiece. The centre core is usually made of high-strength materials to withstand the high pressure and temperature generated during the moulding process.

Left Mold Part: The left side of the mould is responsible for forming a part of the workpiece, and at the same time, it is able to spread outwards to release the workpiece during demoulding. The connection between the left mould and the central core is designed to ensure a tight fit during moulding and a smooth separation during demoulding.

Right Mold Part: The Right Mold Part is similar to the Left Mold Part in that it is responsible for forming the other part of the part and unfolds outward during demolding. The connection design between the right side mould and the centre core also needs to be precise to ensure the moulding quality and release effect.

Manufacturing process of three-piece collapsible moulds

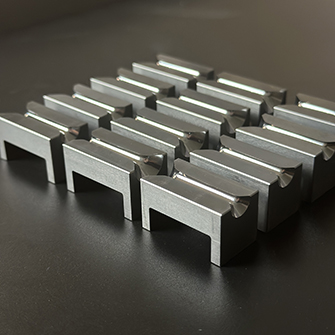

Material Selection:The choice of material for manufacturing a three-piece collapsible mould is of paramount importance. Usually use high-strength alloy steel, stainless steel or other materials with good mechanical properties and heat resistance. These materials can maintain stable performance under high pressure and high temperature moulding environment to ensure the durability of the mould and moulding quality.

Mould design:Mould design is a key step in the manufacturing of three-piece collapsible moulds. The design process needs to consider a number of factors such as the moulding process, release mechanism, material flow and so on. Modern CAD/CAM software plays an important role in mould design, which is able to carry out accurate 3D modelling and simulation to optimize the mould structure and function.

Processing and manufacturing:The processing and manufacturing process of mould includes CNC machining, heat treatment, surface treatment and other links. CNC machining technology can achieve high-precision mould parts manufacturing, ensuring the dimensional accuracy and fit precision of each part. Heat treatment process improves the hardness and abrasion resistance of the mould material and prolongs the service life of the mould. Surface treatment such as chrome plating, titanium plating, etc. can improve the corrosion resistance and lubricity of the mould surface, and further improve the moulding quality.

Assembly and debugging: After the mould parts are processed, they need to be assembled and debugged precisely. The assembly process needs to ensure that all parts of the close coordination and correct positioning, debugging process needs to be tested and adjusted many times on the mould to ensure that the molding quality and demoulding effect to meet the expected requirements.

Application areas of three-piece collapsible moulds

Automobile manufacturing: In the automobile manufacturing industry, three-piece collapsible moulds are widely used in the production of all kinds of complex shapes of parts, such as engine cases, intake manifolds, instrument panels and so on. Its high precision and high efficiency moulding ability makes the production of these complex parts become more economical and reliable.

Home Appliances Manufacturing:Many parts in home appliances, such as the shell of washing machines and the internal components of air conditioners, are also often manufactured using three-piece collapsible moulds. This mould design can effectively improve production efficiency and reduce production costs.

Medical Devices:In the field of medical devices manufacturing, three-piece collapsible moulds are used to produce various complex shapes of device parts, such as syringes, catheter connectors, etc. The three-piece collapsible moulds are also used to manufacture the internal components of air conditioners. The high precision and cleanliness of the moulding requirements make this mould an important application in the production of medical devices.

Electronic products:electronic products in the shell, connectors and other complex parts are also often used three-piece collapsible mould for production. Its excellent moulding ability and precision to ensure the quality and performance of electronic products.

Advantages of three-piece collapsible mould

High-efficiency moulding: three-piece foldable mould can complete the complex shape of the workpiece moulding in one mould, reducing the multi-process operation and improving the production efficiency.

Precise demoulding: Through the clever design of three-piece structure, the mould can be smoothly unfolded during demoulding, avoiding damage to the workpiece in the process of demoulding, and improving the yield rate.

Cost Reduction: As the three-piece collapsible mould can efficiently complete the production of complex parts, the number of moulds and processes can be reduced, thus lowering the production cost.

Extended application: this mould design is suitable for a variety of materials and a variety of moulding processes, including injection moulding, die-casting moulding, etc., has a wide range of application prospects.

The future development trend of three-piece collapsible moulds

Intelligent manufacturing: with the development of intelligent manufacturing technology, three-piece collapsible mould will be combined with intelligent manufacturing technology, using intelligent perception, intelligent control and intelligent decision-making technology, to improve the automation and production efficiency of the mould.

Application of new materials: the development and application of new materials will further enhance the performance of three-piece foldable moulds, such as the use of high-strength, high-temperature-resistant new alloy materials, to improve the service life of the mould and moulding quality.

3D printing technology:The progress of 3D printing technology provides new possibilities for mould manufacturing. Through 3D printing technology, prototypes of moulds with complex structures can be manufactured quickly, improving the efficiency and flexibility of mould design and manufacturing.

Customised production:With the diversification and individualisation of market demands, three-piece collapsible moulds will play an important role in customised production. Through flexible design and manufacturing, it can meet the specific needs of different customers and provide personalised mould solutions.

As an innovative mould design, the three-piece collapsible mould has shown significant value in the manufacturing industry with its advantages of efficient moulding, precise release, cost reduction and wide range of applications. Despite the challenges of complex design, high manufacturing cost, high material requirements and difficult maintenance, three-piece collapsible moulds will usher in a broader development prospect with the development of intelligent manufacturing, new material application, 3D printing technology and customised production. In the future, three-piece collapsible moulds will continue to play an important role in improving production efficiency, reducing production costs and meeting personalised demands, providing strong support for the development of the manufacturing industry.