As a professional mold manufacturer in China, we provide high-quality Three-Piece Collapsible Molds that offer innovative core-collapse functionality for producing undercut or deep-cavity plastic parts without side actions. Our molds are widely used in industries such as packaging, medical, personal care, and automotive.

This advanced collapsible core mold system allows for efficient molding and easy demolding of complex geometries, reducing cycle time and improving mold longevity.

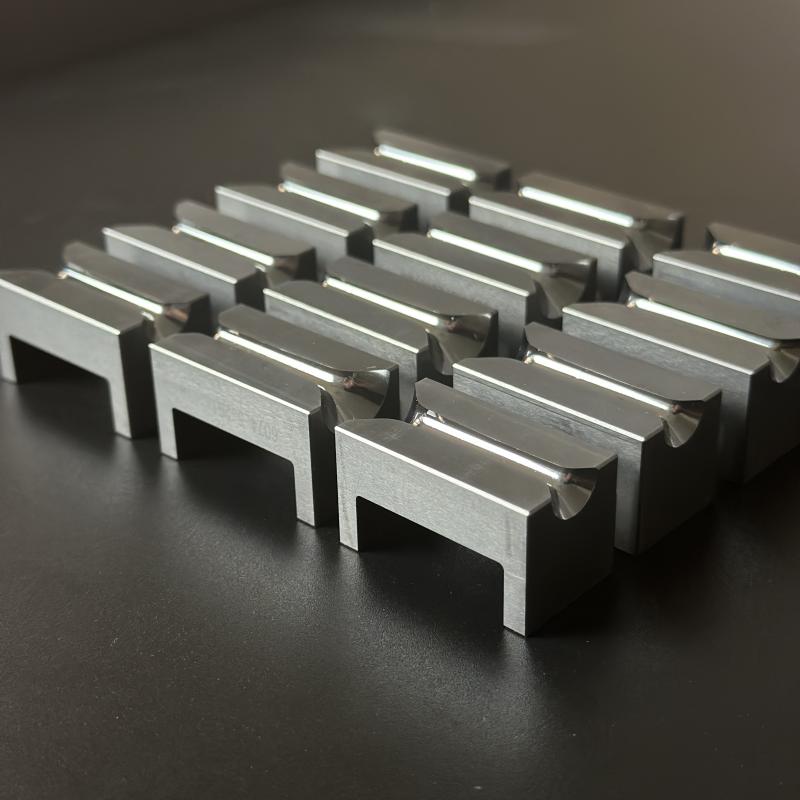

Our Three-Piece Collapsible Molds are made with high-precision components, utilizing hardened tool steel, CNC-machined inserts, and high-tolerance collapsible cores. These molds are designed for high-volume production and are compatible with most standard injection molding machines.

The collapsible core is divided into three segments that retract inward after molding, allowing the molded part to be released without the need for additional sliders or hydraulic mechanisms. This compact design improves efficiency and reduces mold complexity.

We support custom Collapsible Mold design based on your part drawings, including solutions for deep-hole products, thread demolding, and internal undercuts.

The working principle of the Three-Piece Collapsible Mold is based on its unique construction design. The mold consists of an upper mold, a lower mold, and an intermediate mold, which can be collapsed with either the upper or lower mold. During the injection molding process, the mold is first closed and the upper and lower molds are clamped together to fill the mold cavity with injected plastic. When the molding cycle is complete, the middle mold is folded, allowing a portion of the molded part to be easily removed from the mold without excessive force. This folding design greatly simplifies the process of removing the molded part, improves ease and safety of operation, and reduces damage to the molded part. This type of mold is suitable for the production of parts that require complex internal structures, bringing convenience and efficiency to the production process.

1.High Precision Molding with Core-Collapse Technology

2.No Side-Actions Required, Ideal for Undercuts and Threads

3.Faster Cycle Time Compared to Traditional Thread Unscrewing Molds

4.Compact Mold Structure, Easy to Maintain and Install

5.OEM and ODM Services Supported

6.Compatible with Various Injection Molding Machines

All molds are manufactured under strict quality control and undergo trial runs before shipment.

Our Three-Piece Collapsible Mold solutions are trusted by:

1.Plastic packaging factories

2.Medical and pharmaceutical product manufacturers

3.Household and personal care brands

4.Precision injection molding companies

5.OEM/ODM mold developers

6.Export-oriented plastic product makers

If you are looking for a collapsible core mold supplier in China, we offer reliable engineering support, short lead times, and consistent after-sales service to global customers.

Over 27 years of experience in mold making

Professional team with mold design and assembly capabilities

Support for complex part structures and collapsible mold mechanisms

ISO-certified factory with full-scale CNC and EDM equipment

Serving customers in Europe, North America, Southeast Asia, and the Middle East

FAQ:

How does the three-piece collapsible mold work?

The three-piece collapsible mold consists of upper mold, lower mold and middle mold. The middle mold can be folded with either the upper mold or the lower mold. During the injection molding process, the mold is closed and plastic is filled into the mold cavity. After molding, the middle mold folds so that part of the molded part can be easily removed from the mold.

In which industries are three-piece collapsible molds widely used?

three-piece collapsible molds are widely used in plastic products, medical devices, electronic products and other industries, and are especially suitable for the production of parts requiring complex internal structures.

What are the advantages of three-piece collapsible molds over traditional molds?

Compared with traditional molds, three-piece collapsible molds allow molded parts to be removed from the mold more easily, reducing damage and improving operational convenience.

What are the options for manufacturing materials for a three-piece collapsible mold?

The three-piece collapsible mold is usually made of high-quality tool steel or carbide to ensure the strength and wear resistance of the mold.

How to ensure the stability and safety of mold folding?

The folding design of the mold has been precisely calculated and rigorously tested to ensure stability and safety when folded to prevent accidents.

What types of product production is this mold suitable for?

Suitable for the production of products requiring complex internal structures, such as parts with holes or hollow parts.

What are the maintenance methods for three-piece collapsible molds?

Maintenance methods include regular cleaning, lubrication maintenance, regular inspection and regular maintenance to ensure the stability and performance of the mold.

What is the future development direction of three-piece collapsible mold technology?

Future development directions may include optimizing design, improving production efficiency and improving material technology to meet increasingly complex product production needs.

Three-Piece Collapsible Mold Product Information | |

Product Name | Three-Piece Collapsible Mold |

Brand Name | Donglong |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Material for Core of Three-Piece Collapsible Mold | ||||||

Grade | WC+Other | Co | Grain Size | Density | Hardness | TRS |

(±0.5%) | (±0.5%) | (g/cm³) | (HRA)±0.5 | (N/mm²) | ||

KG5 | 88 | 12 | Medium | 14.31 | 88.3 | 340 |

KG6 | 86 | 14 | Medium | 14.12 | 87.3 | 320 |

EA65 | 82 | 18 | Coarse | 13.75 | 85 | 300 |

EA90 | 76 | 24 | Coarse | 13.22 | 82.8 | 270 |

ST6 | 85 | 15 | Coarse | 13.8 | 86 | 270 |

ST7 | 80 | 20 | Coarse | 13.4 | 85.3 | 270 |

VA80 | 80 | 20 | Coarse | 13.58 | 84 | 280 |

VA90 | 78 | 22 | Coarse | 13.39 | 82.5 | 240 |

VA95 | 75 | 25 | Coarse | 13.12 | 81.5 | 220 |

Material for Casing of Three-Piece Collapsible Mold | |||

Material | Hardness (HRC) | Features | Applications |

H13 | 59-61 | H13 is a chromium molybdenum hot work steel with exceptional hot hardness and abrasion resistance, general hardness, and toughness. | Used for extrusion dies, forging dies, stamping tools, etc. |

SKD11 | 58-61 | SKD11 tool steel has good wear resistance and size ability after heat treatment. | Used for tensile dies, cold extrusion dies, first punch holder, etc. |

SKD61 | 43-53 | SKD61 steel is a high-grade die casting die. It has heat shock resistance, heat deformation resistance, heat fatigue resistance. | Used for heat work dies, cold heading dies, second punch holders. |