In Cold Heading processing, the Transfer Finger is an essential die component, especially in a multi-die header Cold Heading Machine. Its primary function is to precisely transfer metal blanks from one die cavity to the next, directly impacting the shape, size, and quality of the final product. Understanding the Transfer Finger’s functionality, design, performance, and application scenarios can help you make the most informed decision when selecting tooling for your manufacturing process.

The Transfer Finger is responsible for precisely transferring metal blanks from one die cavity to another during cold heading processing. Through high-precision transfer, it ensures that the blanks remain in the correct position and orientation throughout the forming process, preventing any potential processing deviations.

During the transfer process, metal blanks may experience head deformation or shoulder sagging, leading to quality issues. The Transfer Finger effectively prevents these deformations, ensuring that each product maintains the desired quality.

By utilizing a Transfer Finger, downtime for mold adjustments and alignment is minimized. It streamlines the transfer process, improving overall production efficiency, accelerating production speeds, and reducing the time spent on machine setup and maintenance.

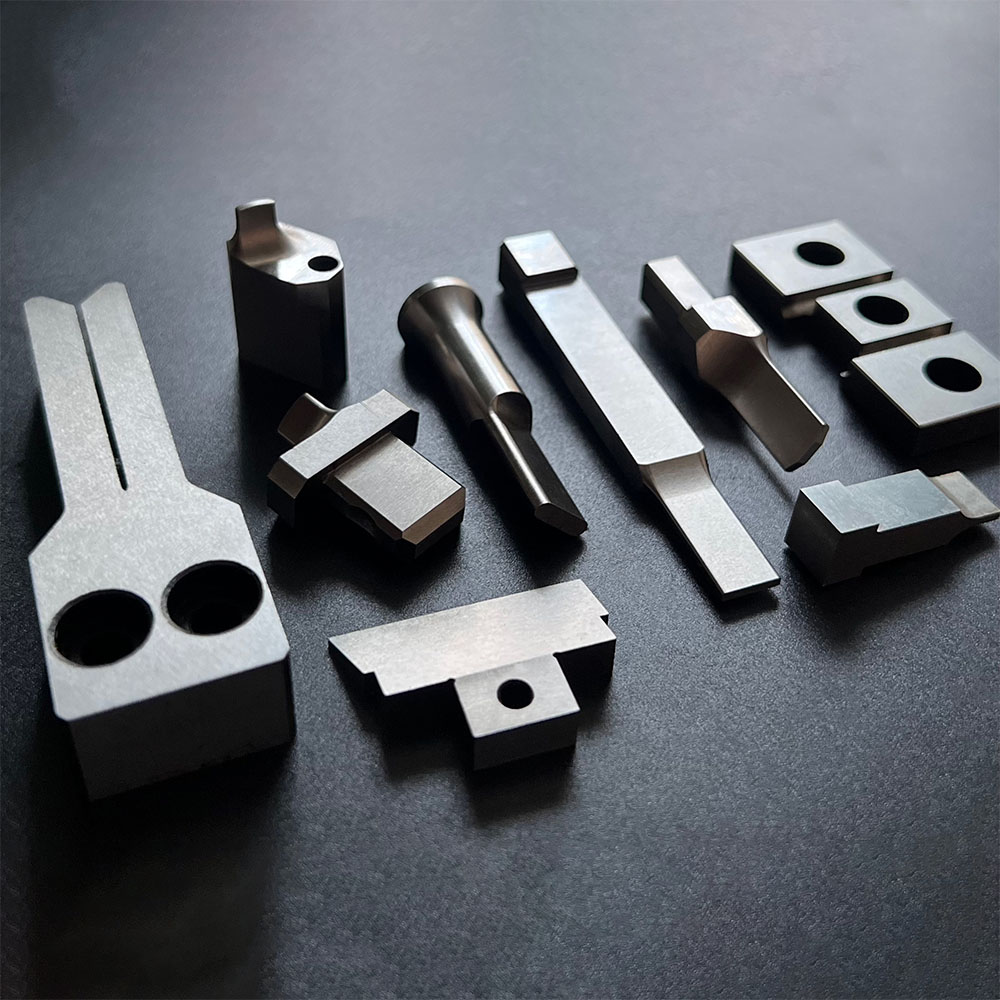

Due to the unique geometries and size requirements of different products, the Transfer Finger is typically designed to be custom-made. By offering personalized designs, the Transfer Finger can be tailored to better suit specific processing conditions and product needs.

The Transfer Finger is commonly made from cold-rolled steel that offers excellent wear resistance and corrosion resistance, making it suitable for high-intensity cold heading environments. The material is also treated to enhance durability and fatigue resistance, ensuring stable performance over the long term.

Manufacturing a Transfer Finger requires the use of high-precision machining techniques to ensure its dimensions and shape are accurate. The precise manufacturing process allows the Transfer Finger to maintain stable performance throughout the cold heading process, ensuring consistent and reliable metal blank transfers.

In multi-die header cold heading machines, the Transfer Finger is one of the most essential components. It efficiently and precisely transfers metal blanks between multiple die cavities, ensuring product consistency and quality throughout the entire cold heading process.

For parts with complex shapes and stringent dimensional requirements, the Transfer Finger plays a critical role. It ensures that every detail of these complex parts adheres to the design specifications without any deviation in position or orientation.

The Transfer Finger is suitable for a wide range of cold heading machines and can handle various metal materials. Whether it's steel, aluminum, or other alloys, the Transfer Finger ensures precise transfers, optimizing the processing of different materials.

With its precise design and manufacturing, the Transfer Finger ensures the accurate positioning and orientation of the metal blanks during transfer. This contributes to the high precision of the final product, meeting demanding quality standards.

Made from high-quality cold-rolled steel, the Transfer Finger boasts superior wear resistance and corrosion resistance. It can withstand the harsh cold heading environment, offering extended service life and stable performance over time.

By reducing mold adjustments and aligning time, the Transfer Finger significantly boosts production efficiency. It optimizes the processing flow, reduces manual intervention, and keeps the production line running smoothly, saving both time and costs.

We offer fully customized Transfer Finger solutions tailored to your specific product needs. Whether it's for a specific die or material type, our Transfer Fingers are designed to meet your unique manufacturing requirements.

The Transfer Finger is an indispensable component in cold heading processing. With its precise transfer mechanism, durable materials, and high-precision manufacturing, the Transfer Finger helps enhance cold heading processing accuracy and efficiency, ensuring consistent product quality and reducing production errors.

By utilizing Transfer Finger, the increased production efficiency and consistent product quality will directly improve your return on investment (ROI). Reduced downtime and machine setup time lead to lower overall production costs, keeping your production line efficient and cost-effective.

We provide comprehensive technical support to help you maximize the performance of your Transfer Finger. If any issues arise during usage, our after-sales team will offer quick, professional solutions, ensuring your production process remains uninterrupted.

A Transfer Finger is a critical component used in multi-die header cold heading machines to transfer metal blanks from one die cavity to the next. This ensures that the blanks maintain the correct position and orientation, preventing deformation during the forming process and ensuring the final product meets required quality standards.

The Transfer Finger plays a crucial role in preventing deformation such as head distortion or shoulder sagging during the transfer process. By ensuring precise and accurate transfer, it helps maintain the shape and dimensional accuracy of the final product, significantly improving product quality.

Yes, Transfer Fingers are often customized to meet the specific requirements of different products. The design, size, and materials can be tailored based on the geometry, dimensions, and material type of the product being manufactured.

Transfer Fingers are typically made from cold-rolled steel due to its high wear resistance and corrosion resistance. This material choice ensures that the Transfer Finger can withstand the high-intensity conditions of cold heading processing, providing durability and long service life.

By facilitating precise transfers between die cavities, the Transfer Finger reduces machine downtime caused by mold adjustments and alignment. This increases the overall speed and efficiency of the production process, leading to higher productivity and reduced operational costs.

If you're using a multi-die header cold heading machine and need to transfer metal blanks between multiple cavities with high precision, a Transfer Finger is an essential component. It is particularly useful for producing parts with complex shapes and tight dimensional tolerances.

The lifespan of a Transfer Finger depends on factors like the material being processed, the operating conditions, and the frequency of use. However, due to the high-quality materials and precision manufacturing used, Transfer Fingers are designed to offer long-lasting durability, ensuring stable performance over time.

To customize a Transfer Finger, we take into account factors such as product geometry, dimensions, material type, and specific cold heading process requirements. Our design team works closely with you to create a custom solution that fits perfectly with your production needs.

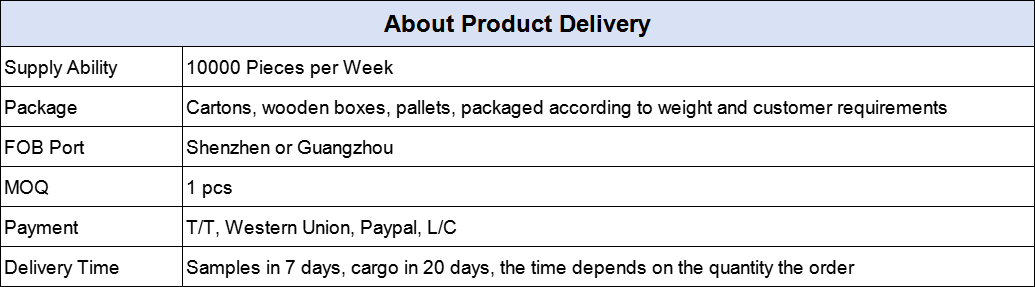

Transfer Finger Product Information | |

Product Name | Transfer Finger |

Brand Name | Donglong |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Material for Core of Transfer Finger | ||||||

Grade | WC+Other | Co | Grain Size | Density | Hardness | TRS |

(±0.5%) | (±0.5%) | (g/cm³) | (HRA)±0.5 | (N/mm²) | ||

KG5 | 88 | 12 | Medium | 14.31 | 88.3 | 340 |

KG6 | 86 | 14 | Medium | 14.12 | 87.3 | 320 |

EA65 | 82 | 18 | Coarse | 13.75 | 85 | 300 |

EA90 | 76 | 24 | Coarse | 13.22 | 82.8 | 270 |

ST6 | 85 | 15 | Coarse | 13.8 | 86 | 270 |

ST7 | 80 | 20 | Coarse | 13.4 | 85.3 | 270 |

VA80 | 80 | 20 | Coarse | 13.58 | 84 | 280 |

VA90 | 78 | 22 | Coarse | 13.39 | 82.5 | 240 |

VA95 | 75 | 25 | Coarse | 13.12 | 81.5 | 220 |

Material for Casing of Transfer Finger | |||

Material | Hardness (HRC) | Features | Applications |

H13 | 59-61 | H13 is a chromium molybdenum hot work steel with exceptional hot hardness and abrasion resistance, general hardness, and toughness. | Used for extrusion dies, forging dies, stamping tools, etc. |

SKD11 | 58-61 | SKD11 tool steel has good wear resistance and size ability after heat treatment. | Used for tensile dies, cold extrusion dies, first punch holder, etc. |

SKD61 | 43-53 | SKD61 steel is a high-grade die casting die. It has heat shock resistance, heat deformation resistance, heat fatigue resistance. | Used for heat work dies, cold heading dies, second punch holders. |