An Automotive Forging Mold is a high-precision tooling system designed for the volume forming of solid metal components used in automotive and New Energy Vehicle (NEV) applications. Unlike stamping molds that process sheet metal, forging molds shape metal billets through cold forging, warm forging, or hot forging, delivering superior mechanical strength, dimensional accuracy, and structural integrity.

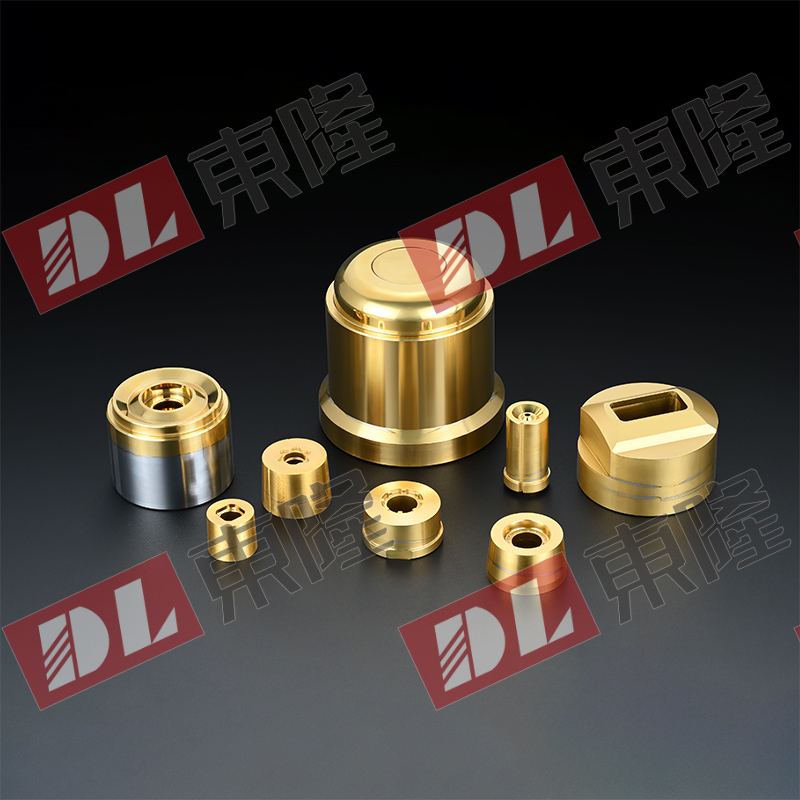

Our automotive molds / automotive moulds / auto mold solutions are engineered with a modular mold core and mold sleeve structure, featuring cylindrical forging cavities, replaceable inserts, and high-concentric stepped geometries. These characteristics make them ideal for precision die forging of critical automotive and EV components where durability, consistency, and long service life are essential.

As a professional manufacturer of automotive forging molds and precision forging dies, we provide custom die solutions for new energy vehicles, supporting high-volume production with stable quality and extended tool life.

The automotive forging mold operates based on metal volume forming, not sheet deformation.

Billet Preparation

Metal billets (steel, aluminum alloy, copper alloy, or other engineering metals) are cut to size and pre-treated according to the forging process (cold, warm, or hot).

Precision Alignment & Guidance

The billet is positioned within a cylindrical forging cavity, formed by a high-strength mold sleeve and a precisely machined mold core. High concentricity ensures uniform material flow.

Forging & Material Flow Control

Under controlled pressure from a forging press, the billet undergoes:

The precision forging die controls metal flow direction, reduces internal defects, and ensures consistent geometry.

Extrusion

Upsetting (heading)

Sizing or reshaping

Ejection & Cycle Repeat

The forged part is ejected, and the mold is ready for the next cycle, enabling high-efficiency mass production.

This process delivers parts with higher density, superior fatigue resistance, and better mechanical properties than stamped or machined components.

Modular mold core + mold sleeve design

Cylindrical forging cavities for stable material flow

Replaceable inserts for reduced maintenance cost

High concentricity stepped structures for dimensional accuracy

Manufactured from high-strength tool steels

Optimized heat treatment for hardness and toughness balance

Optional surface treatments (polishing, coating, nitriding)

Designed for long production cycles in automotive manufacturing

Tight tolerances suitable for precision forging die applications

Excellent surface finish reduces post-machining requirements

Consistent part quality across large batch production

Designed to meet the strength and reliability requirements of EV powertrain and structural components

Supports lightweight materials commonly used in new energy vehicles

Stable performance under high-load and high-frequency forging conditions

Reduced material waste compared to machining

Higher material utilization rate

Lower unit cost in medium to high-volume automotive production

Our automotive forging molds are widely used in both traditional automotive and New Energy Vehicle die applications, including:

Transmission components

Steering system parts

Suspension system components

Shafts, pins, bushings, and connectors

Die for New Energy Vehicles battery system components

Motor and drive unit forged parts

EV structural reinforcement components

High-strength connectors and mounting elements

These automotive molds and automotive moulds are essential for producing safety-critical and load-bearing components in modern vehicles.

Our auto mold and automotive forging mold solutions are compatible with a wide range of forging equipment:

Cold forging presses

Warm forging presses

Hot forging presses

Hydraulic forging machines

Mechanical presses

The mold design can be optimized based on press tonnage, stroke, production speed, and automation requirements.

Each automotive forging mold is produced under strict quality control using a mature and traceable manufacturing workflow:

Technical Review & Engineering Analysis

Customer drawings or samples evaluation

Forging feasibility and material flow simulation

Mold Design & Optimization

Precision die forging structure design

Mold life and stress optimization

CNC Machining & Precision Processing

CNC turning and milling

High-accuracy cavity machining

Critical tolerance control

Heat Treatment

Hardening and tempering

Stress relief to ensure dimensional stability

Surface Finishing & Polishing

Mirror or functional surface finish

Optional wear-resistant surface treatments

Assembly & Testing

Trial fitting

Concentricity and dimensional inspection

Final Quality Inspection

Visual inspection

Functional testing before delivery

We specialize in custom automotive molds and precision forging dies, offering:

Custom die for new energy vehicles based on drawings or samples

Material selection consulting

Mold life optimization solutions

Small-batch prototyping to mass production support

Engineering assistance for complex forging structures

Our team supports projects from concept and design to final production, ensuring each automotive forging mold meets both technical and commercial objectives.

Q1: What is the difference between an automotive forging mold and a stamping mold?

A forging mold is used for solid metal volume forming, while stamping molds are designed for sheet metal forming. Forged parts offer higher strength and durability.

Q2: Are your molds suitable for New Energy Vehicle applications?

Yes. We provide New Energy Vehicle die solutions specifically designed for EV battery, motor, and structural components.

Q3: What materials can be forged using your precision forging die?

Common materials include carbon steel, alloy steel, aluminum alloys, copper alloys, and other engineering metals.

Q4: Can the mold core be replaced?

Yes. Our automotive forging mold adopts a modular structure with replaceable mold cores, reducing maintenance costs and downtime.

Q5: Do you support custom automotive moulds for specific equipment?

Absolutely. We design automotive molds / automotive moulds / auto mold solutions based on your forging press specifications and production requirements.