An Ejection Sleeve, also referred to as an Ejector Sleeve or Sleeve Ejector, is a precision mold component designed to assist in the controlled ejection of molded or formed parts from a tooling system. It is commonly used when a standard ejector pin alone cannot provide sufficient contact area, force distribution, or stability during the ejection process.

Ejection sleeves are especially suitable for parts with:

Central cores

Hollow structures

Bosses or tubular features

Thin walls or delicate geometries

By surrounding the core or ejector pin, the sleeve ejector ensures uniform force transmission, reduces localized stress, and minimizes the risk of part deformation or surface damage.

In a typical ejector sleeve system, the sleeve moves axially together with the ejector plate while sliding smoothly around a fixed or moving core pin. During the ejection stroke:

The ejector system is activated

The ejector sleeve advances forward

Even pressure is applied to the part’s inner or outer surface

The molded or formed part is released cleanly from the cavity

This mechanism provides better alignment, smoother movement, and higher repeatability compared to conventional ejector pins.

Injection mold ejector sleeve

Plastic mold ejector sleeve

Precision ejector sleeve for high-cavity molds

Thin-wall or high-gloss plastic components

Progressive die ejector sleeve

Stamping die ejector sleeve

Metal forming ejector sleeve

Internal feature support during stripping

Die casting ejector sleeve

Heavy-duty ejector sleeve for high-pressure environments

High-temperature ejector sleeve solutions

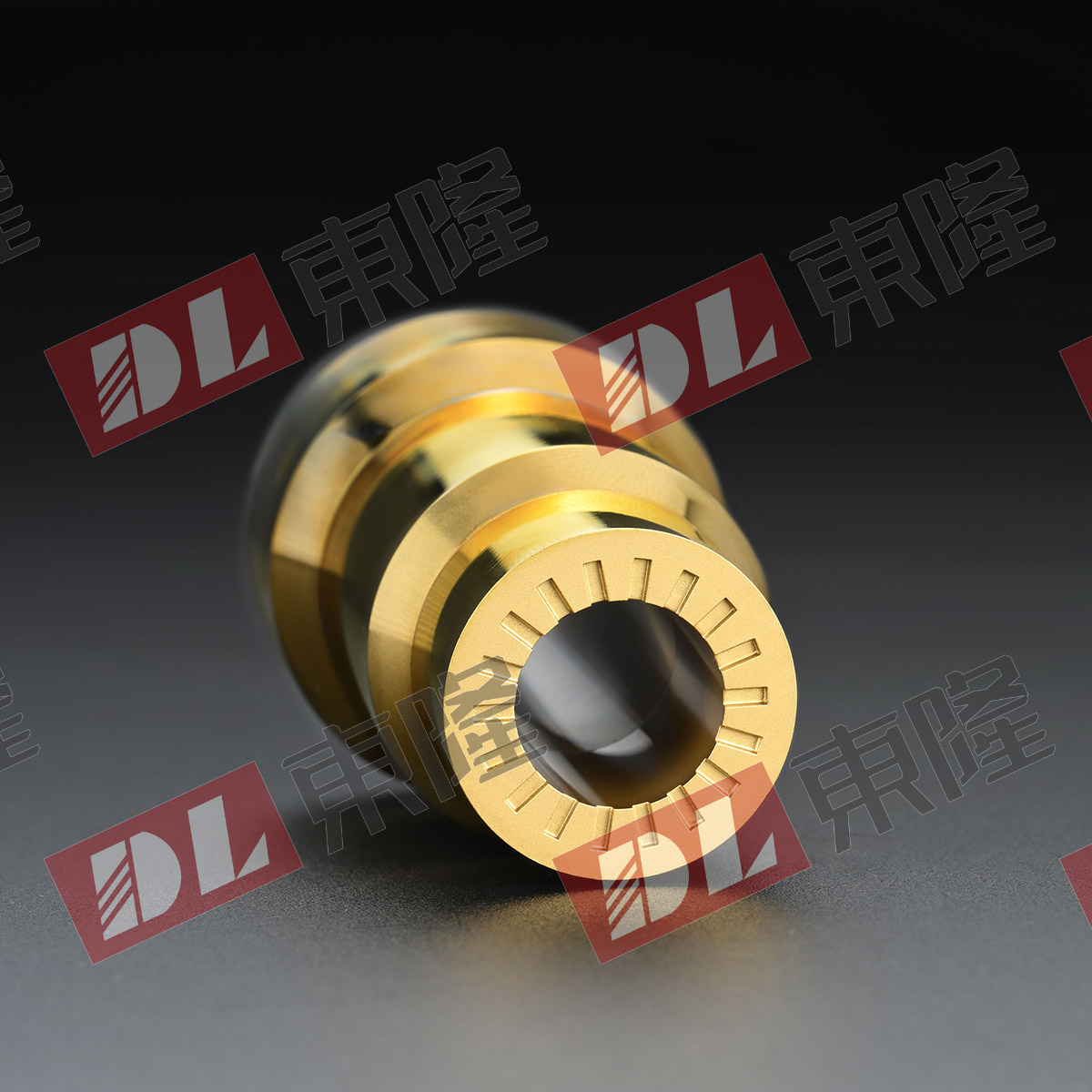

Our precision ejector sleeves are produced using advanced CNC machining, internal and external grinding, and fine polishing processes to ensure:

Excellent concentricity

Tight dimensional tolerances

Smooth sliding surfaces

Stable alignment with mating components

To withstand repeated cycles and high loads, our ejection sleeves are manufactured from premium materials such as:

H13 / SKD61 tool steel

Pre-hardened alloy steel

Tungsten carbide ejector sleeve options for extreme wear conditions

Optional surface treatments include:

Nitriding

Hardening & tempering

Polishing or coating for reduced friction

A properly designed hardened ejector sleeve offers:

Reduced galling and abrasion

Lower maintenance frequency

Extended mold service life

Stable performance in mass production

We specialize in custom ejector sleeves and OEM ejector sleeve manufacturing, supporting:

Non-standard sizes

Special inner/outer diameter tolerances

Custom clearances

Application-specific designs

Drawings, samples, or technical requirements are fully supported.

High-precision inner and outer diameter control

Optimized clearance for smooth axial movement

Excellent compatibility with ejector pins and cores

Suitable for high-speed and high-volume production

Optional lubrication grooves or surface treatments

| Feature | Standard Ejector Pin | Ejection Sleeve |

|---|---|---|

| Contact area | Small | Large |

| Load distribution | Concentrated | Even |

| Part protection | Limited | Excellent |

| Wear resistance | Moderate | High |

| Suitable for complex cores | ❌ | ✅ |

Automotive components

Consumer electronics

Medical and healthcare products

Industrial hardware

Precision metal forming and tooling

An ejector pin applies force at a single point, while an ejection sleeve distributes force evenly around a core or feature. This makes ejector sleeves more suitable for delicate, hollow, or precision parts.

You should consider a sleeve ejector when:

The part has a central core or boss

Surface marks must be minimized

Higher ejection force is required

Part deformation needs to be avoided

Common materials include:

H13 / SKD61 tool steel ejector sleeve

Tool steel with heat treatment

Tungsten carbide ejector sleeve for extreme wear applications

Material selection depends on molding temperature, cycle time, and load conditions.

Yes. We offer custom ejector sleeves based on:

Customer drawings

Samples

Specific tolerance or surface requirements

OEM and non-standard designs are fully supported.

Tolerance requirements vary by application, but precision ejector sleeves typically require:

Tight concentricity control

Optimized clearance with mating components

Smooth surface finish to prevent sticking or galling

Absolutely. Ejector sleeves are widely used in:

Progressive stamping dies

Metal forming tools

Die casting molds

especially where higher load and durability are required.

By reducing localized stress and wear on ejector pins and cores, a high-quality ejector sleeve system:

Minimizes component failure

Reduces downtime

Extends overall tooling life

A well-designed ejection sleeve is a critical component for achieving reliable, precise, and damage-free mold ejection. Whether used in injection molding, stamping dies, or die casting, a precision ejector sleeve significantly enhances part quality, production efficiency, and mold durability.

As an experienced ejector sleeve manufacturer and supplier, we provide high-quality materials, precision machining, and full customization support to meet demanding tooling applications.